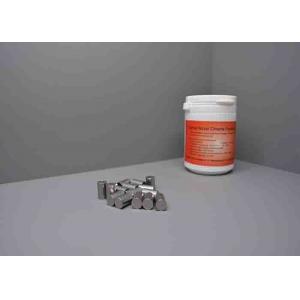

This is NiCr Porcelain Metal Free Beryllium (hard type)

- Product Application Range: Suit dental labs for casting crowns, bridges and combination.

- Spec. & Model:KC-I(Nickel-chrome Porcelain Alloy)

- Summary:KC series porcelain alloy is constitute of nickel-chrome porcelain alloy(KC-I) and cobalt-chrome porcelain alloy(KC-II). This product according as Shanghai Factory Standard YZB/Hu3815-60-2008 and Standard YY0621-2008 and YZB/SHCP02-2009, and made by cobalt, chrome , molybdenum and so on. The performance of alloy is good and easy to use.

- Physical and Chemistry Performance:

| |

- b. Coefficient of expansion: 14.3×10-6/℃ (20~500℃)

|

| |

- d. Break off/craze original intension≥26 Mpa

|

- e. Tensile strength: ≥260 N/mm2

|

- f. Alloy liquidus or solidus curve temperature: 1260~1350℃

|

- g. Modulus of elasticity: 210 GPa

|

- h. Corrosion resistance 7d above the release of ions is less than total average accumulation 0.1 mg/cm2

|

- i. Alloy composition(%):Nickel 60~64; Chrome 23~27; Molybdenum 9~13; Silicon<2.5; Others<2.0

|

- Equipment

- a. When casting can use high-frequency centrifugal casting machine or spring centrifugal casting machine. Casting after dissolved by acetylene-oxygen.

- b. Casting can use casting furnaces for crowns and bridges to pre-oxidation and ceramic sintering.

- c. The highest temperature 1200℃ thermocouple temperature control bow-type furnace and blast cleaning machine.

- Operation Method

- Mold: In order to ensure casting fluid of mild, thickness of wax-ups should not be less than 0.5mm. Casting pipe can be prepared by ordinary manner. If it is a higher amount of metal crowns or bridges, the experiment proved that can set saving room.

- Investment: Suit for all the investment materials in the market. In the process of removing wax and reheating, should according to the use manual offered by investment factory, especially preheating time. Through validation, the suitable temperature is 900℃.

- Casting: Melting in the ceramic crucibles, and draw the steam out at the same time.

- Note: Do not use graphite crucibles!

- Open flame melt: Using acetylene and oxygen to be fuel. Care the user manual of fuel supplier.

Precisely adjust of flame intensity can affect the purity of alloys.

- HF/open flame melt: Do not need latent solvent. After melting of alloy and shadow disappeared about two seconds, then begin casting.

- After casting, mold ring should cool down, and then deflate. Do not use water to cool down.

- Suggest do not use alloy repeatedly, because in the process of melting, the oxide will vaporize which is important to metal and casing connection. After several times of melting, the composition will be reduce, and it will do harm to the quality of material and casting connection. Then use ordinary stereoplasm alloy file or aluminum oxide ore to process, the thickness of crowns will be at less 0.2mm to 0.3mm. In the processing of different types of alloys, suggest use the same type rotary instruments avoiding influence the alloy.

- Casting material: Should note the coefficient of expansion of the casting material, and cooling time should not be too long.

- Cast Firing: Do not need oxidation firing. If use oxidation firing, should heat to 980℃ for 10min, and then use alumina to spray sand, finally use distilled water washing, ultrasonic washing or steam washing. Washing and firing should according to casting manual. Suggest after firing, do this job after firing plate cool down.

- Promise: The manual is based on our practical experience; the responsibility of the right application is on the user. The loss and compensate requirements due to the manual should refer to the worth of delivery products.

- Cautions

- a. The room of finishing should have good air pump, staff should wear protecting respirator, avoid of inhale metal dust.

- b. This product includes Nickel, the people who have nickel-allergy should be cautious.